1. Chlor-alkali chemical industry

As one of the modern basic chemical industries, chlor-alkali chemical industry is widely used in chemical industry, light industry, textile industry, metallurgical industry, petrochemical industry and public utilities.

Chlor-alkali chemical industry uses the electrolysis of saturated NaCl solution to generate chlorine and NaOH.

The M-CHLOR series high-concentration diaphragm electrolytic sodium hypochlorite generation system developed and produced by Jinan Ou Rui Industrial Co., Ltd. further synthesizes and transforms the generated chlorine and NaOH through the electrolysis of saturated brine to form a high-concentration sodium hypochlorite solution, the concentration of which can reach 12.5% .

It is the original solution of water plant disinfection, 84 disinfectant preparations and commercial sodium hypochlorite.

2. Petroleum refining

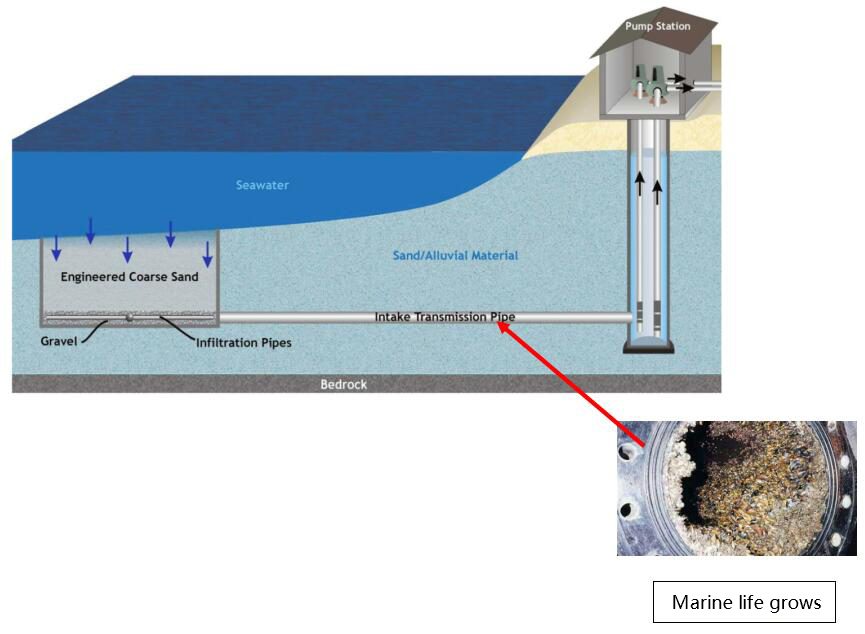

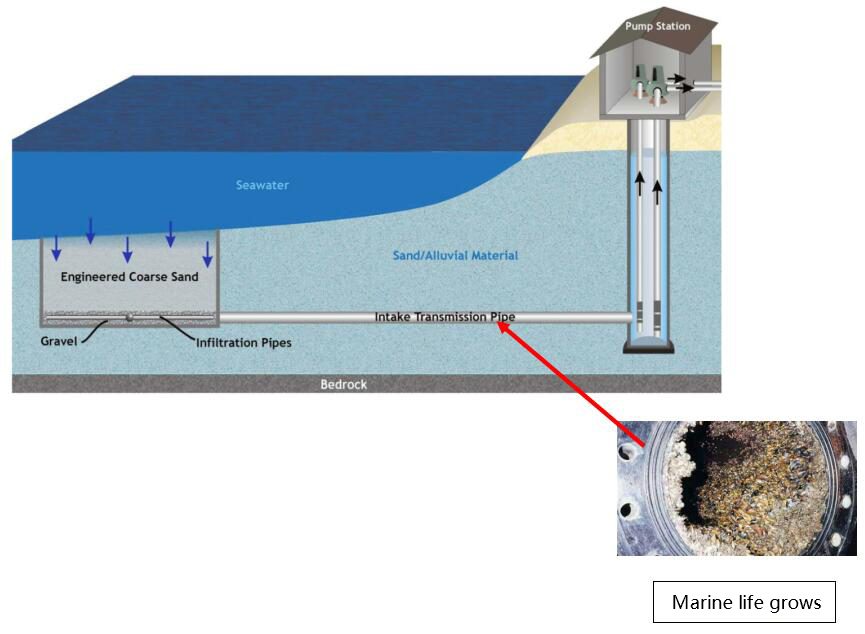

The main process of petrochemical industry, fire fighting and cooling water mainly use seawater as the water source or directly or through pretreatment systems such as seawater desalination. The antifouling of seawater and the elimination of algae have become the top priority.

The electrolytic seawater chlorine production system converts NaCl into NaClO solution by electrolyzing seawater and feeds it into the pretreatment pipeline for seawater antifouling and algae killing.

If the seawater lifting pipeline is blocked, the flow rate will be too low, which will cause the following serious consequences:

●Insufficient amount of hot water exchange leads to limited heat exchange

●Corrosion

●Flow rate is too low

●Blocked pipe

The seawater chlorine production system adopts an economical and safe way to prevent the growth of marine organisms by converting sodium chloride in seawater into sodium hypochlorite.

Compared with the traditional terrestrial electrolytic seawater chlorine production system, the RNH series has a unique petrochemical complete system design, which can achieve an optional high IP level (IP54). Some special hazardous applications can choose to have ATEX, EX, SIL and other explosion-proof and safety integrity level systems.