Ship and Offshore

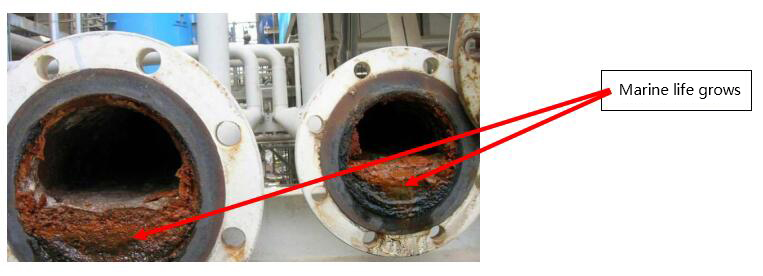

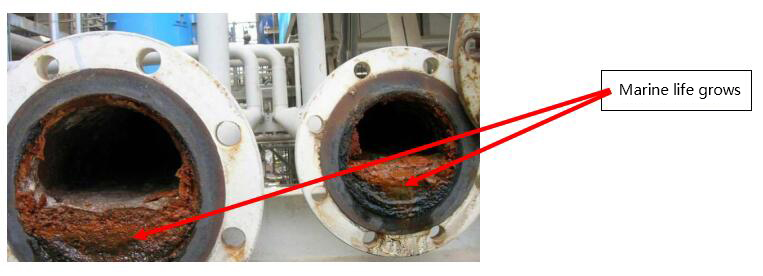

Seawater is the main source of water for ships and offshore platforms, and the antifouling of the seawater lift pump part and the elimination of algae have become the top priority of the hydration part of ships and offshore platforms.

The electrolytic seawater chlorine production system converts NaCl into NaClO solution by electrolyzing seawater and feeds it into the pretreatment pipeline for seawater antifouling and algae killing.

If the seawater lifting pipeline is blocked, the following serious consequences will be caused due to the low flow rate:

●Insufficient amount of hot water exchange leads to limited heat exchange

●Corrosion

●Flow rate is too low

●Blocked pipe

The seawater chlorine production system adopts an economical and safe way to prevent the growth of marine organisms by converting sodium chloride in seawater into sodium hypochlorite.

OCEANCHLOR series of offshore electrolytic seawater type sodium hypochlorite generators produced and developed by Jinan Ou Rui Industrial Co., Ltd.

In order to inhibit the growth of microorganisms and organic matter in the water to form mud scale in the circulating water pipeline, which will reduce the water flow and reduce the heat exchange efficiency, the treatment method of adding sodium hypochlorite to the cooling water is adopted. The electrolytic seawater sodium hypochlorite generator uses natural seawater and adopts high-speed electrolysis to prepare high-activity sodium hypochlorite solution on site. Sodium hypochlorite solution is transported to the dosing point as a biocide through dehydrogenation storage, effectively killing microorganisms, sea creatures, algae and crustaceans in the water body, and preventing the blockage of circulating water pipelines and condenser systems.

Compared with the land electrolysis seawater chlorine production system, the OCEANCHLOR series has a unique offshore electrolytic cell design and an oil-cooled or circulating water-cooled rectifier transformer, which can achieve a pickling-free effect and a high IP rating (IP54). Some special hazardous applications can choose to have ATEX, EX, SIL and other explosion-proof and safety integrity level systems.